Around a year ago Aaron started to learn to play the guitar. One of his hero’s is Tom DeLonge of Blink 182 and Angels and Airwaves. Tom has had a wide variety of guitars and Aaron wanted to own one of his guitars, a replica would be fine, but these are difficult to find and quite expensive if you can find one. The alternative, let’s make one!

We are lucky, we live in an age where you can get almost anything at a reasonable cost, especially if you are not to worried about the quality of what you are getting.

Looking around amazon, eBay and the like you can get pretty much everything to make a guitar, more so you could probably make a guitar pretty close to what you want for less than £100, but building a cheap clone was not the aim.

Step out of the comfort of eBay and Amazon and start searching for more specialised places to get the exact parts that were used on the original and you will find that there are many suppliers of everything you need. Some will make you a complete bespoke design and built to your specification and charge you several £1000’s for the privilege, others specialise in bits of wood either a big block, or something cut to your requirements and then letting you get on with the finishing and painting. The prices still range from ‘ok’ to ‘gulp’, Aaron aimed for the middle ground.

The guitar we are building is based on a Fender Stratocaster, these have not changed much since they were first made, indeed Fender will sell you many of the parts to build/repair a guitar.

The parts….

Many of the parts are not manufacturable without specialist equipment, other parts, like the neck, could be made ‘in the shed’ but are possibly beyond our first build, maybe next time.

A ‘previously enjoyed’ neck was found, a Squire neck (Genuine necks are very expensive, new or old) but apart from the name was identical otherwise.

Bridge, Strings, Tuners, Pickup, Pick guard, Misc. hardware was all sourced to be as close if not identical to the original.

That leaves the body. Aaron found a company that sells a square blank of wood planed the correct thickness and another that sells all the paint in the correct colour.

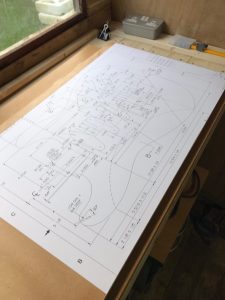

A further search turns up the original drawings for the Fender Stratocaster body. Time to get the wood working tools out!

The preparation….

Never having done anything like this before we needed to do some preparation.

YouTube. As ever there are numerous channels on YouTube that cover making guitars, from the one-man hobbyist with a few tools to the custom guitar shops that have massive workshops and every tool imaginable. After watching several hours of people making guitars, we found a few techniques that we could use.

The practice….

Aaron had never used a router before, time to stick some small plans to a piece of MDF and have some practice.

The build, templates….

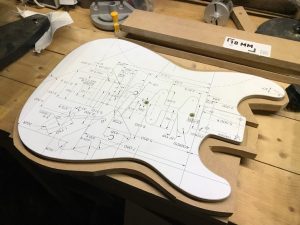

Easiest way to accurately route the wood is to create some templates, then use these to run the router around. Two are needed, one for the body cut-outs and another for the outline of the body.

Testing the templates

The build, the real thing….

Time to chop up the expensive piece of wood!

Rounding the edges